Test Cutting/Technical Consultation (Performance Evaluation)

As a cutting tools manufacturer with growing technological

expertise, we are able to propose a wide range of solutions.

Performance Evaluation

An important point for conducting process improvement activities on-site is not to only rely on personal experiences Tea Cup in Japan intuition but also to clarify problems through visualization of the

machining phenomena with the help of the latest measuring equipment.

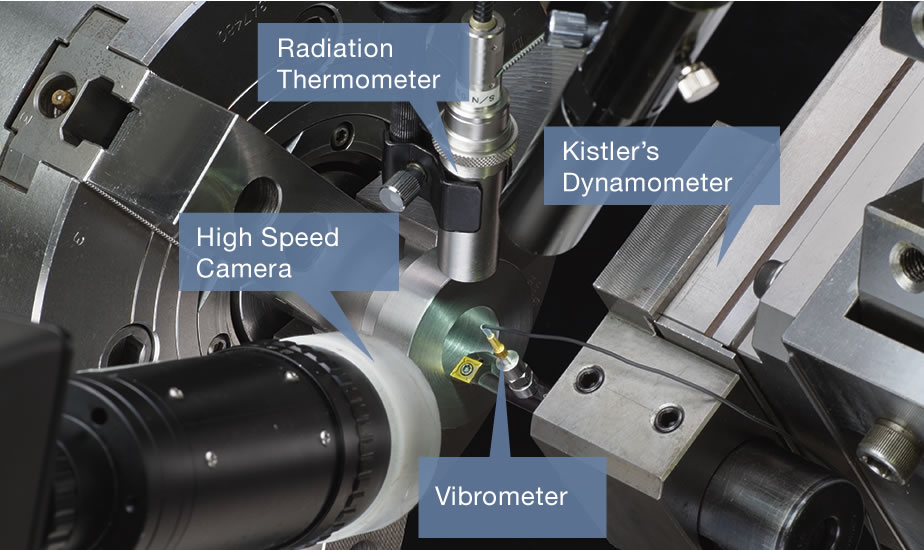

In-Line(in machine) Performance Evaluation

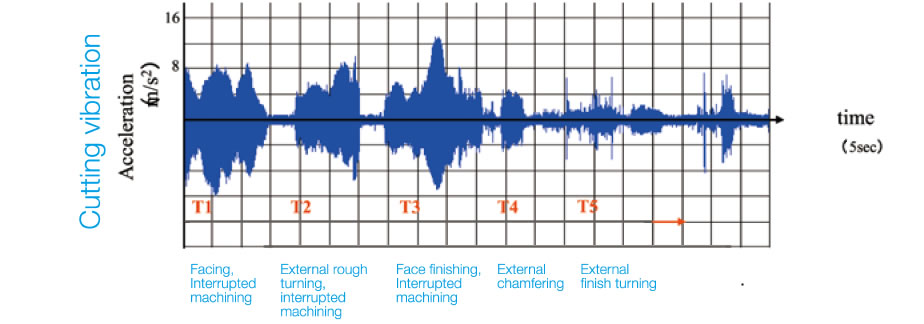

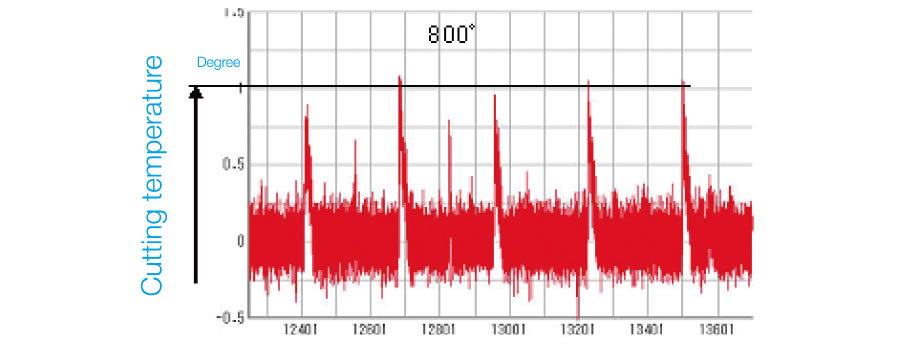

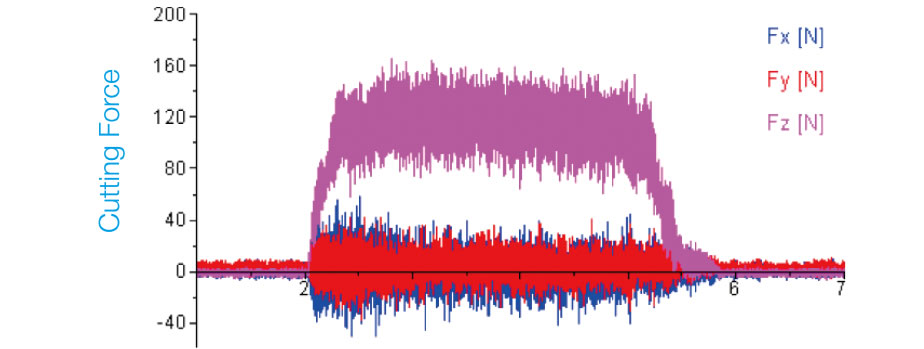

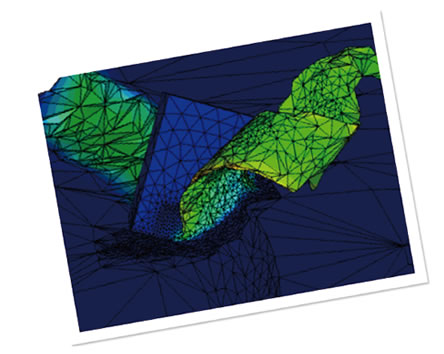

Utilizing high speed camera to observe the machining point along with simultaneous measurements of cutting vibration, cutting resistance, cutting force, displacement and cutting

temperature etc., can provide new findings and more in-depth information on the actual causes.

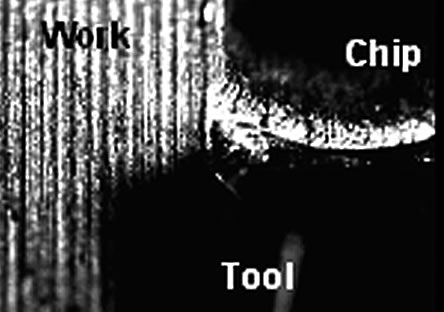

Example of observation by high speed camera

Example of observation of drilling (Drill)

Example of observation of built-up edge (Turning)

Example of measuring cutting vibration

Example of measuring cutting temperature by a radiation thermometer

Example of measuring cutting force by Kistler’s dynamometer

Example of analysis on chips simulation

Off-Line(outside machine) Performance Evaluation

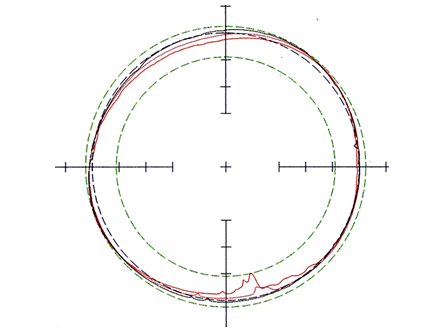

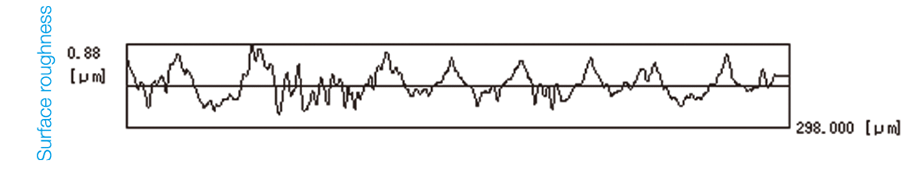

Quality problems on the test cut component can be confirmed through measuring its surface

roughness, roundness and from the tool wear.

Example of measuring surface roughness by a laser displacement meter

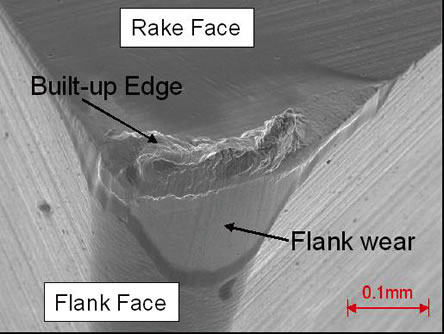

Photograph of tool wear

Photograph example of tool wear

(SEM = scanning electron microscope)

Example of measuring roundness