GND Grooving Series

GND Grooving Series

GND Brochure 2024

Features & Benefits:

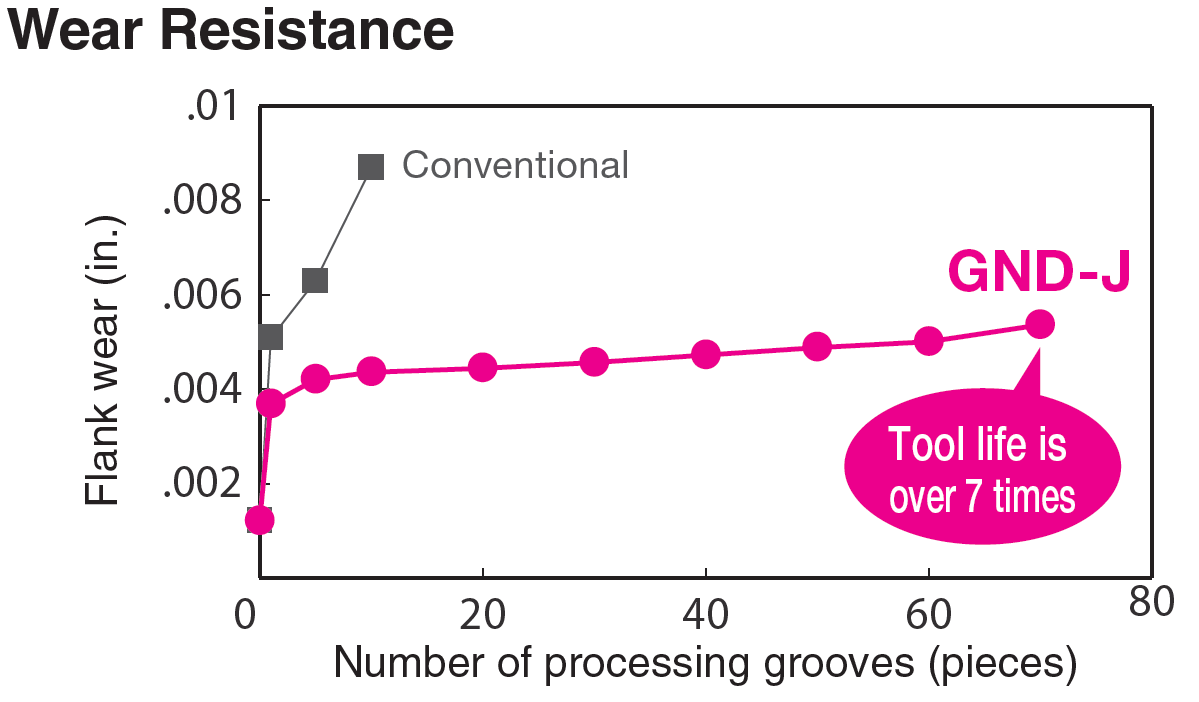

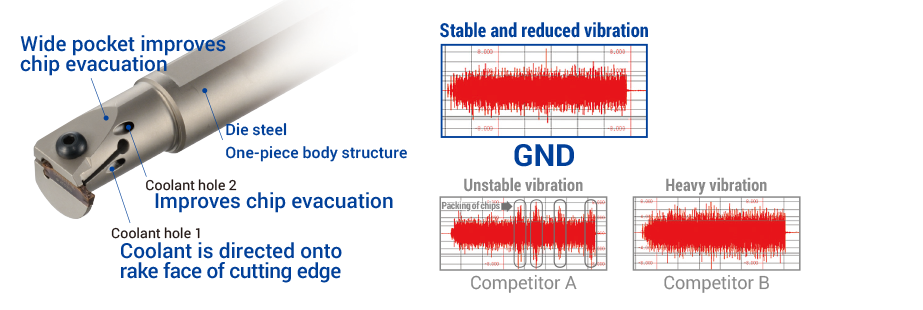

High Rigidity Body

- Utilizing die steel and a one-piece construction to achieve stable machining by suppressing chattering not only in grooving but in turning, profiling and facing operations.

A variety of Chipbreakers

- GND series has a lineup of 10 different chipbreakers for different machining applications.

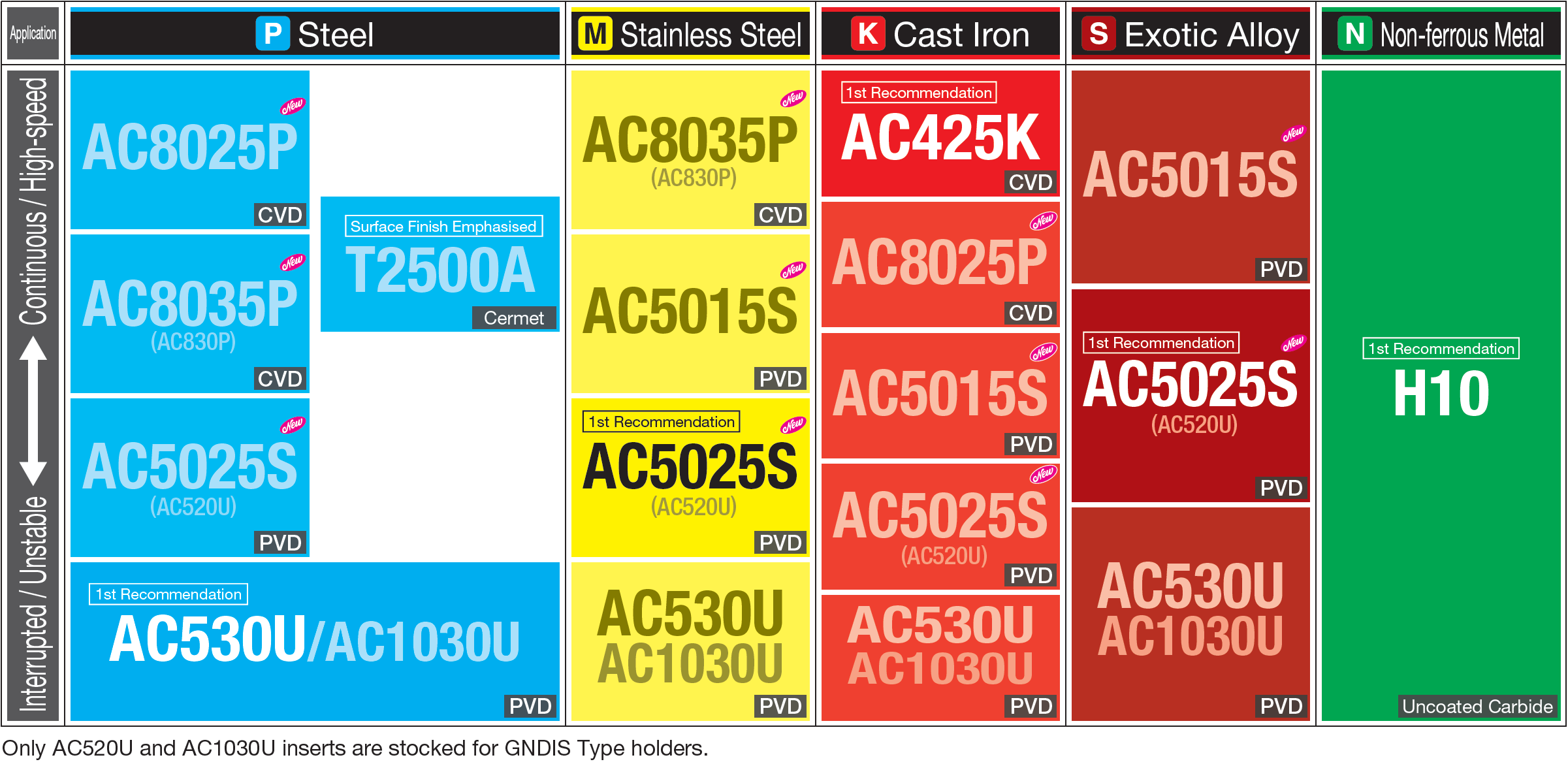

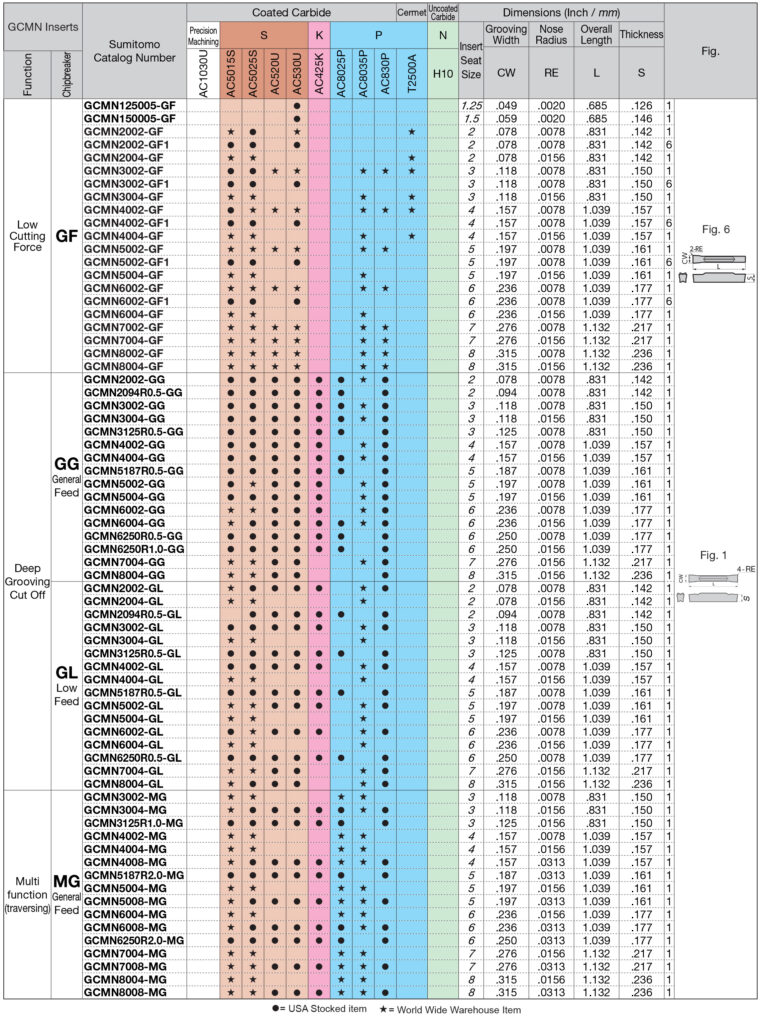

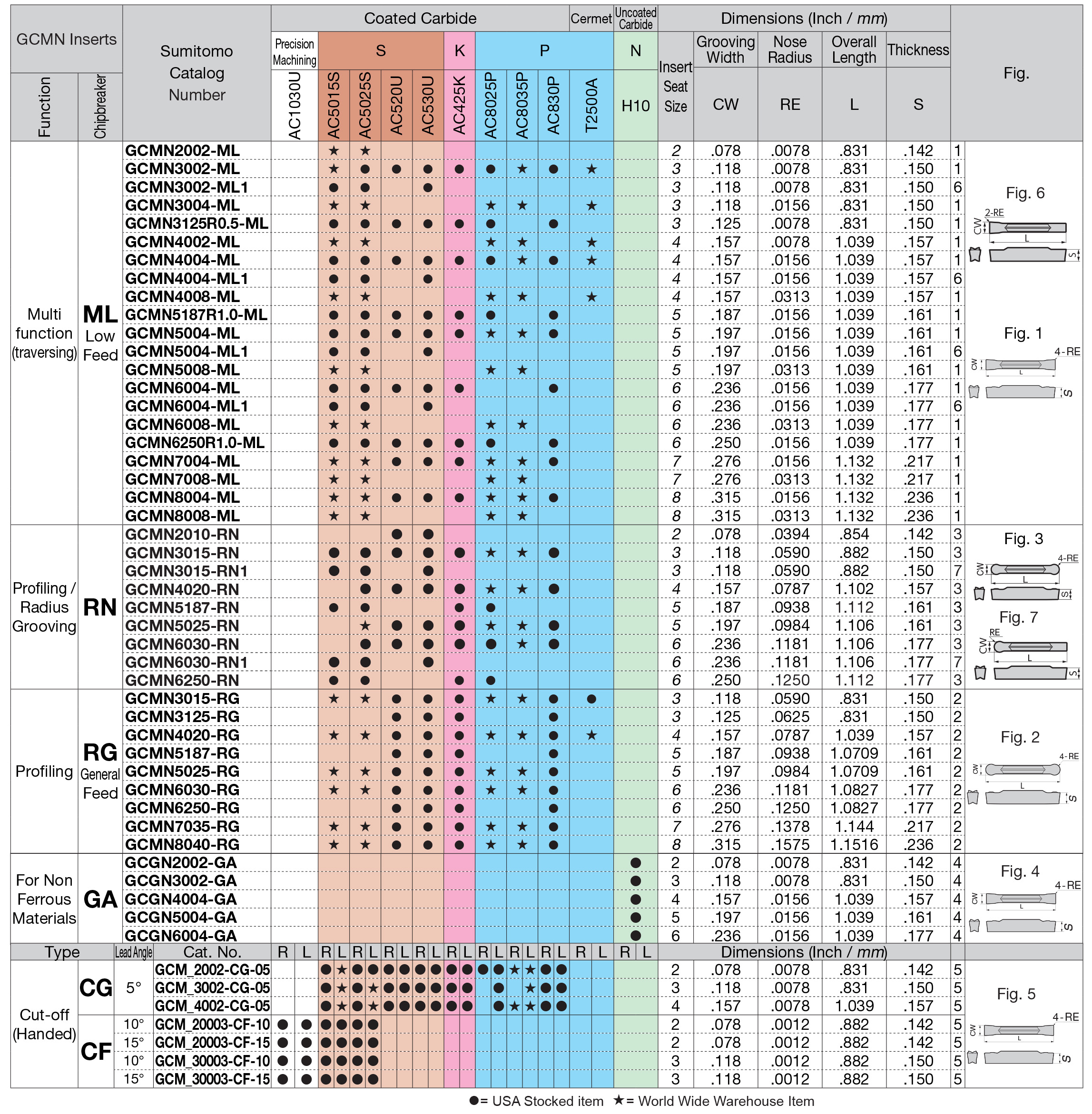

Insert Selection:

Chipbreaker for Cut-off Machining

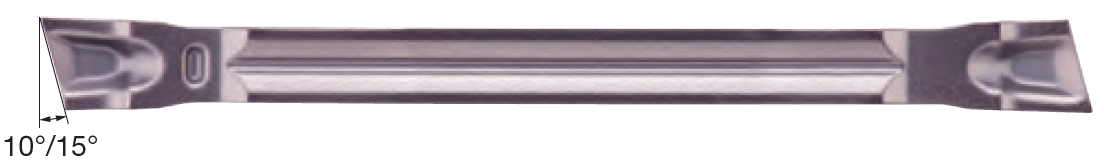

CF Type:

- Lead angle of 10° – 15° for improved sharpness in cut-off machining.

- Asymmetrical chipbreaker design provides excellent chip control even in difficult to machine conditions.

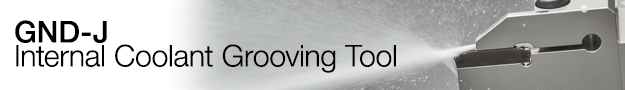

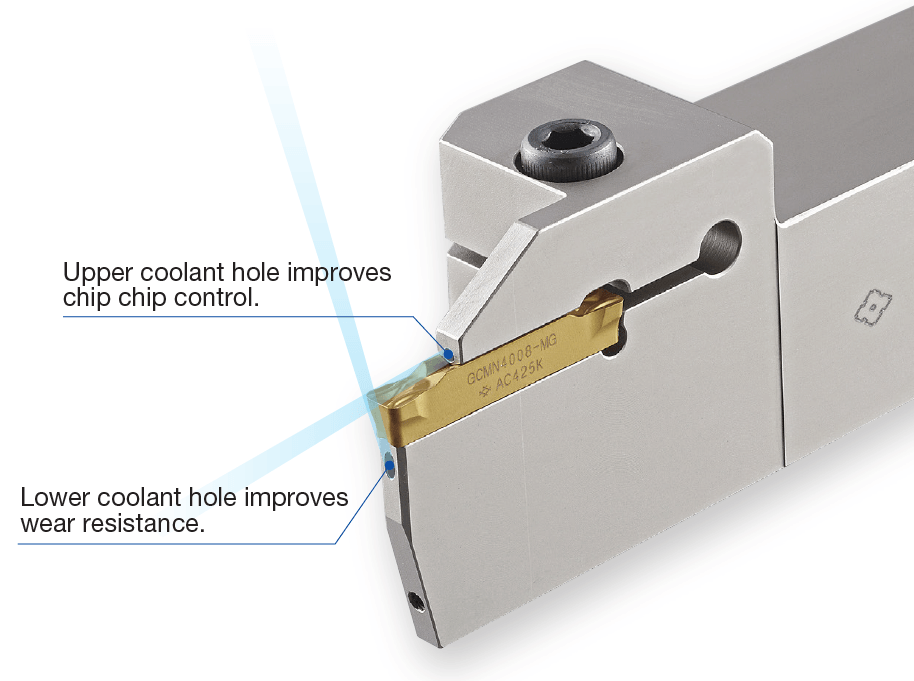

GND-J: Internal Coolant Grooving Tool:

– Newly developed 2-hole coolant through design optimizes cooling of the insert and improves chip removal, extending tool life and allowing for improved speeds and feeds in production.

– Grooving width range from 0.079” to 0.250”.

– Achieves both high effciency in high speed machining and extension of

tool life due to internal coolant supply to the cutting edge.

– Improves chip control by applying direct coolant

from cutting edge side.

Cutting Performance:

Eliminated Chattering

- High rigidity design reduces chattering up to 30% better than conventional tools.

Material: Cr–Mo steel

Holder: GNDL R2525M-220

Insert: GCM N2002-GG (AC530U)

Cutting Condition: svc=100m/min, f=0.10mm/rev, ap=20.0mm, Wet

Ensures both high rigidity and good chip evacuation performance

Material: Cr–Mo steel

Holder: GNDI R2532-T306

Insert: GCM N3002-GG (AC530U)

Cutting Condition: svc=100m/min, f=0.05mm/rev, ap=3.0mm, Wet

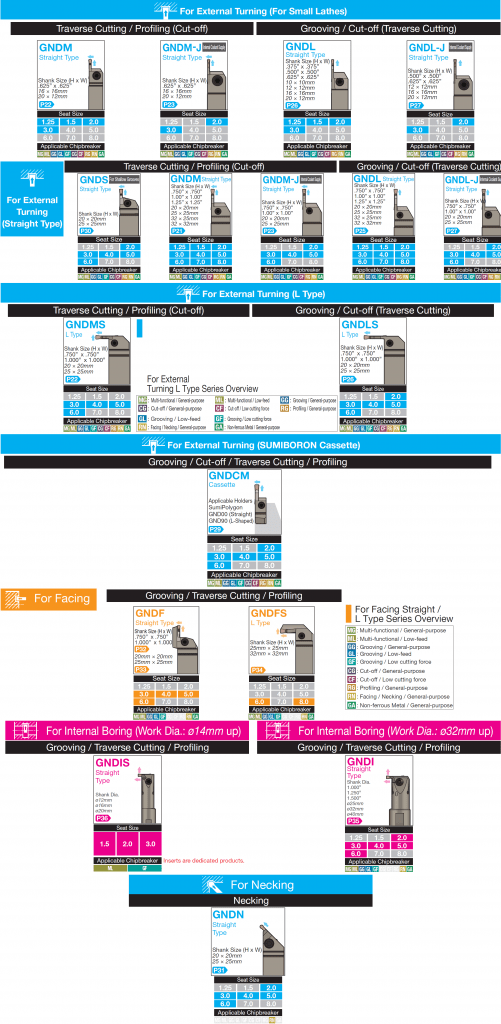

Product Offering by Application:

Items for GND Small Lathes Expanded

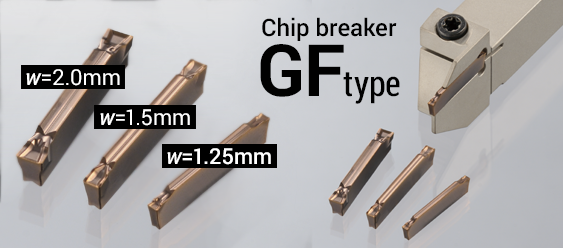

The lineup includes grooving widths of 1.25, 1.5, 2.0, and 3.0mm.

Reduces chattering and achieves high-efficiency machining

Reduces vibration during grooving while inheriting the high holder rigidity of the GND series.

Reduces chip control problems

To improve chip control under various conditions, we have newly added the GF Type to our wide lineup of chipbreakers.

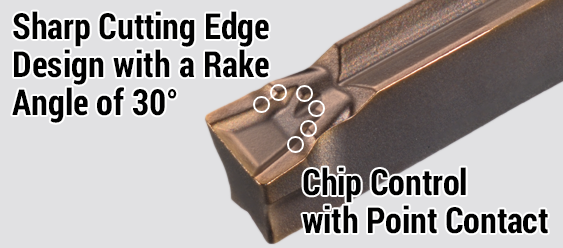

Low Cutting Resistance Chipbreaker GF Type

1. Reduces chattering during cutting.

2. Ideal for machining using low-powered equipment such as small lathes.

3. Reduces adhesion to tools and achieves long tool life in machining of stainless steel, etc.

Achieves excellent chip control and reduced cutting resistance thanks to the sharp cutting edge design with a rake angle of 30°. Also achieves reduced frictional resistance through chip control with point contact.

YouTube: