Brands History Chapter 3

Home > Brands History Chapter 3

Chapter 3: Throw-away Insert Tool Appears

Transition of IGETALLOY Trademark

Sumitomo’s emblem “#” symbolizes the frame of a Japanese old well. Trademark “#IGETALLOY” after a “Sumitomo’s emblem”, which is registered in 1938. It was named after a “hanging rack”, which is Sumitomo’s symbol. It was renamed to “IGETALLOY” in October, 1959 and have been used to this date. Respectful of Sumitomo’s tradition, inspiration and a spirit of challenge given in the trademark “I GET ALLOY” have been inherited until now and is the spiritual pillar of our Powder Alloy Department.

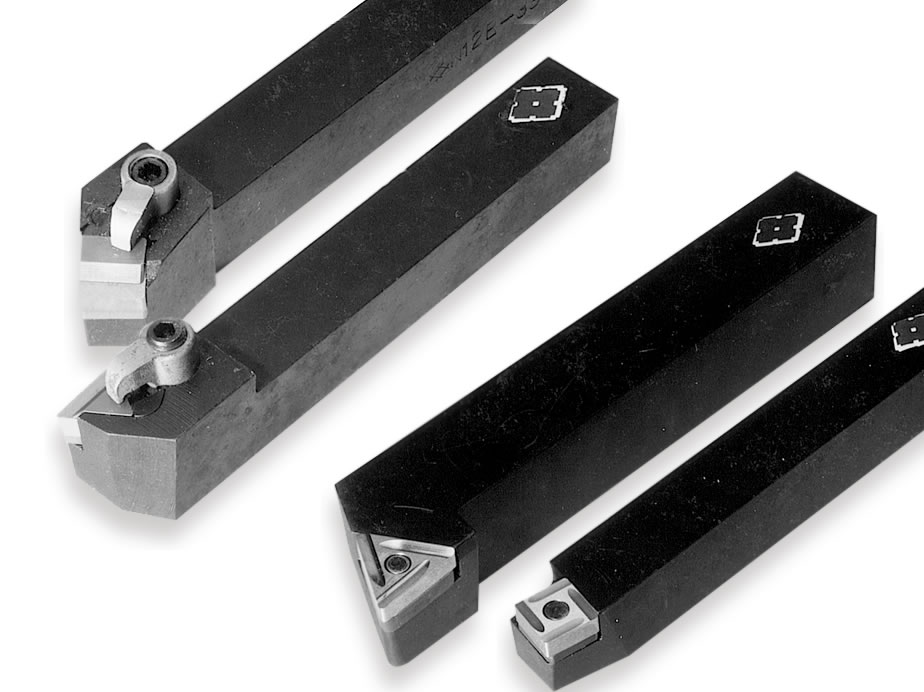

Development of SEC Tool Holders Type 20/30 Series

Using the basic “Type 3 SEC tool holder” form, the cam-lock type “SEC-30 tool holder” and clamp-on type “SEC-20 tool holder” were commercialized in 1966, based on new standards (CIS and JIS).

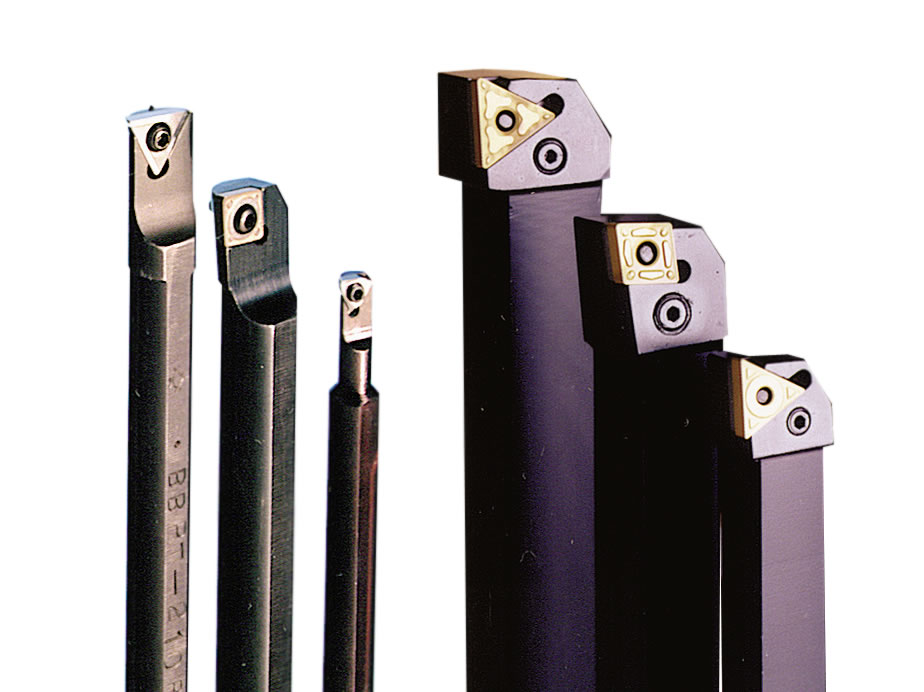

SEC Tool Holder Series

Development of the “SEC-small diameter boring bar” in 1976 and the “SEC-70 tool holder” in 1977, which conforms to the ISO standards, paved the way for the rapid progress of indexable type tools for internal and external turning tools.

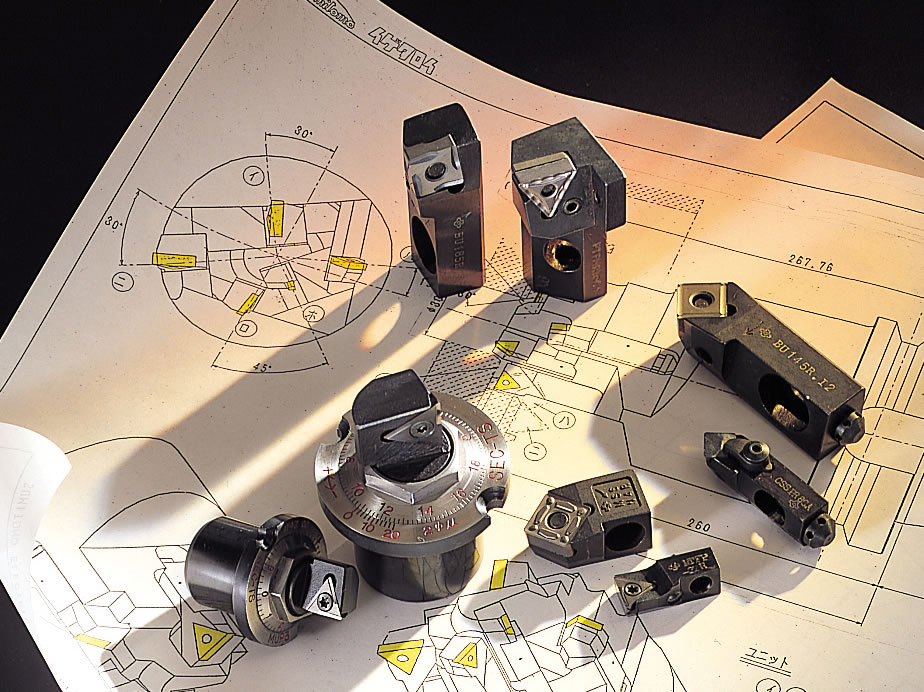

SEC Cartridge Development

Ahead of the industry, the development of the “SEC-Cartridge BU type” in 1968 and the “SEC-Micro Unit MP type” in 1971, were recognized as compound tooling for significant reduction of machining time.

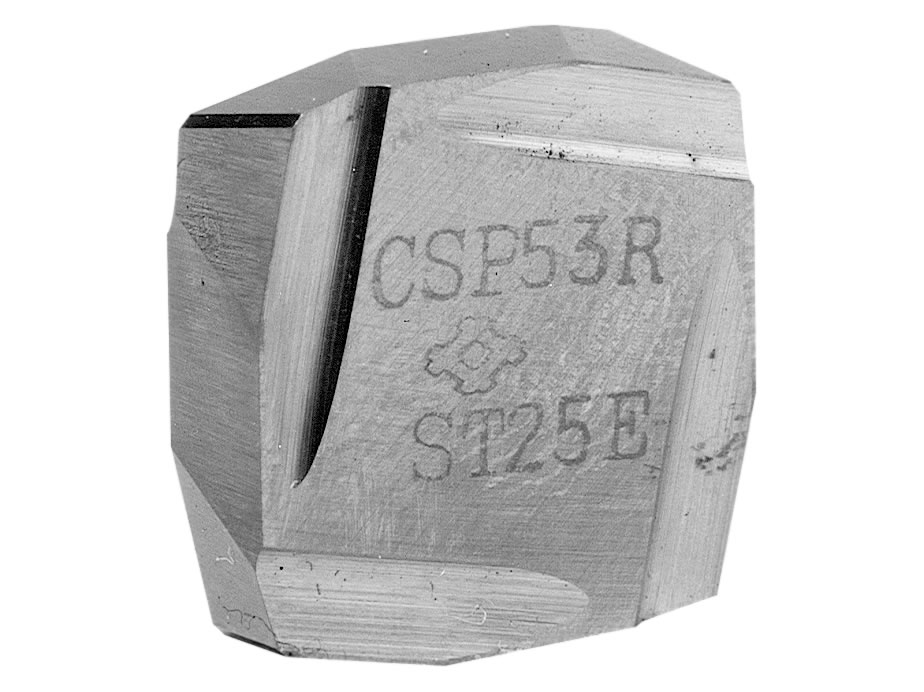

PGM Cutter Insert with Double Sheer Clear Cutting Edges (CSP53R)

SEC-MILL High Clear Series Takes The World by Storm

Applying the development experience of the first domestic made SEC cutter, 3 series of the unique and innovative “SEC-MILL High Clear Series” were released in July 1966. Among the series, the PGM type was the most popular and dominated the industry as a bestselling product.

IGETALLOY “E Series” Development

In the 1960s, IGETALLOY new “E Series” grades (ST20E / U10E / G10E) were developed in succession and were mainly used for brazed cutting tools and throw-away tips. They are also stored in the “Time Capsule EXPO70” to commemorate the Osaka Expo (in Osaka Castle Park).

IGETALLOY Long Roll

For the purpose of making large sized alloys, we manufactured the nation’s largest cemented carbide roll (60mm diameter × 1,400mm length) using a static pressure mold (rubber press) around 1962 and received a Top Ten New Product Award from Nikkan Kogyo the next year in 1963.