Brands History Chapter 1

Home > Brands History Chapter 1

Chapter 1: The Birth of “IGETALLOY” Cemented Carbides

Cemented Carbide Dies and Cutting Tool

Cemented carbide dies, the origin of cemented carbide tool “IGETALLOY”, were successfully produced as wire and cable drawing dies for private use in 1928 but were later commercialized in 1931. They were first exported to U.S. immediately after the war in 1947. On the other hand, cutting tools started from the research/study of bites for grooving in-house rolls, and were commercially marketed in 1931 under the brand name “IGETALLOY Hard Alloy”. In 1935, we started to sell Type S steel cutting tools (which contained Ti and Ta).

Kyukichi Shinba

A research report in October 1929 by Kyukichi Shinba (doctor of engineering who was engaged in this company from 1924 to 1947) gives us an idea of how he failed at project after project, using selected materials and refined facilities until he finally could produce cemented carbide in his own way.

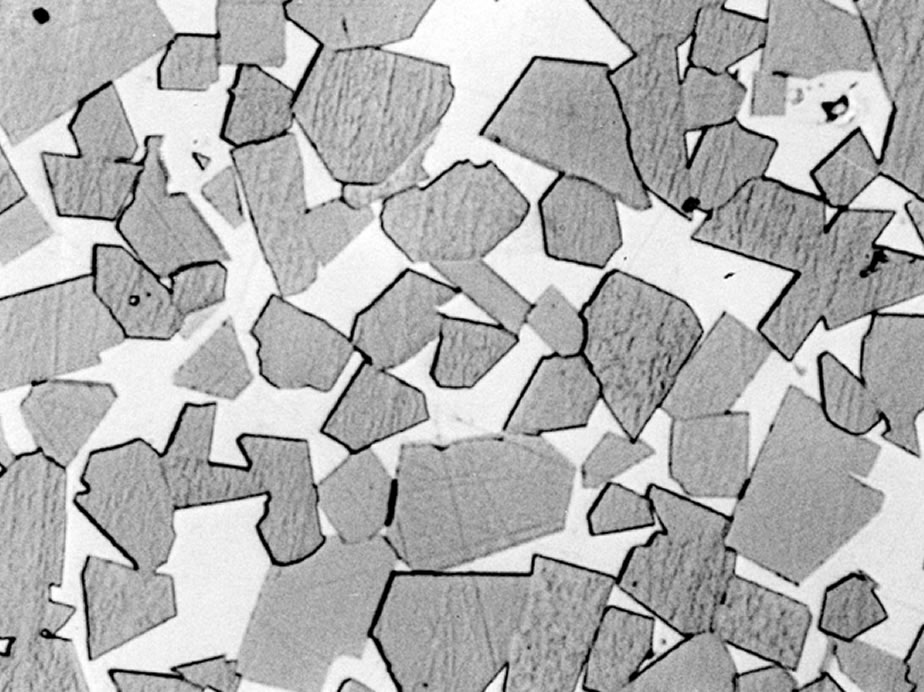

Wc-Co Composition Photo (Example)

Production in wartime (around 1941)

Production scene of carbide dies polishing operations with women inspectors sitting side-by-side. In recorded history, 1,200 male workers and 880 female workers were engaged in producing IGETALLOY in 1944, producing two tons of it monthly.

Production in wartime (around 1941)

In wartime they were polishing cemented carbide dies or female inspectors were working on a specific gravity measurement sitting side by side. In recorded history 1,200 of male workers and 880 of female workers were engaged in producing IGETALLOY in 1944, producing two tons of it monthly.

Introduction of Mining Tools

In the postwar reconstruction period, to address the increase in coal production policies, mining tools for coal mining and rock drilling such as “auger drill”, “coal cutter bit” and “rock bit” were developed as top-priority issues paving the way for IGETALLOY’s new usage as it entered its peak.

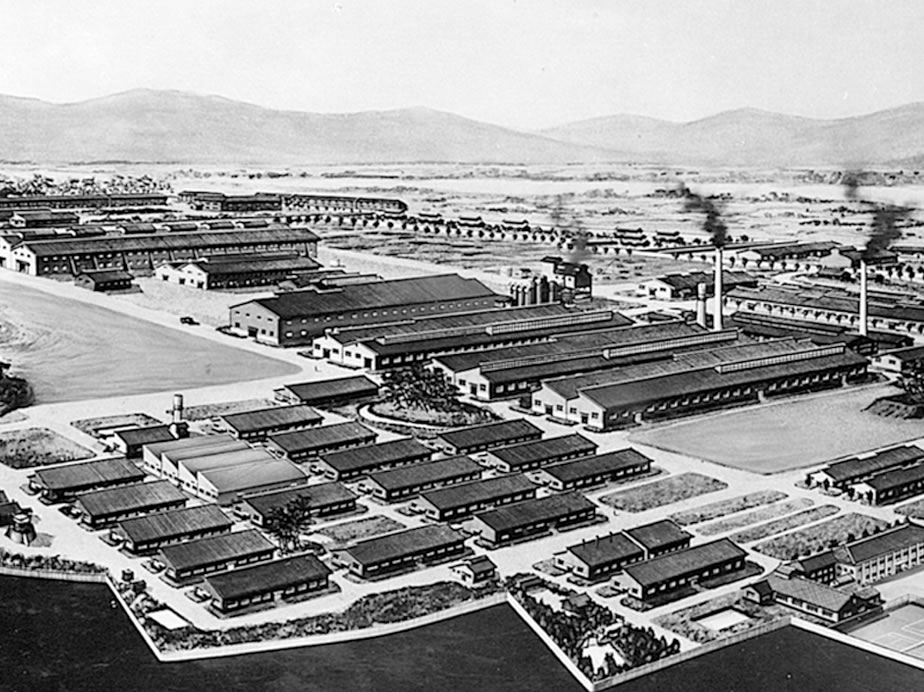

Bird’s-eye View of Itami Works from South West (around 1952)

Itami Works started operations in March 1941 in response to increased production of IGETALLOY. The IGETALLOY factory kept full production mainly for military demands during wartime, but demands decreased significantly right after the war. Then, a special procurement boom associated with the Korean War and the roaring coal industry helped Itami Works’ gradual reconstruction. Factories also started to expand and upgrade their presence. For IGETALLOY, five wooden factories were lined up from South at East side of the main alloy factory; cutter, dies, cutting tool, machinery, and inspection buildings.

Former Research Building No. 7

This oldest wooden building in the premises still retain some remnants of those days when Itami Works opened (currently power materials warehouse). Used as No. 7 research building (Itami 2nd. Research Section) in 1950s, where a ceramic tool “ALOX” was born.