Cermet Grades

Cermet Grades

T1500A Feature & Benefits:

General purpose cermet grade that provides both wear and fracture resistance, and better quality finished surfaces

Economical alternative to carbide in finishing applications

A tough, high strength cermet grade produced from an optimized balance of tough / hard and ultra-hard grains

Improved oxidation resistance coupled with a smooth edge treatment generates excellent mirror-like surface finishes

T1500Z Feature & Benefits:

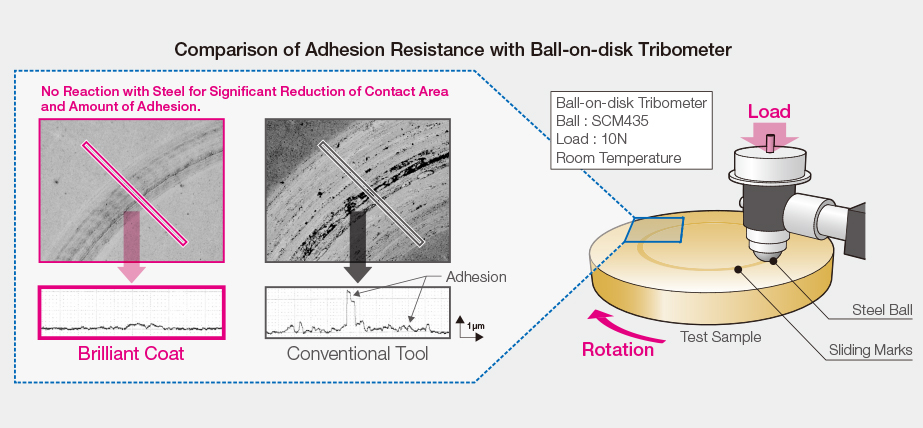

General purpose coated cermet grade that employs Sumitomo’s new Brilliant CoatTM PVD coating with excellent lubricity for longer tool life

Excellent wear resistance, adhesion resistance, and fracture resistance adds tool life- reducing your cost per part

Expanded chipbreaker lineup with newly developed “EFB” type gives excellent chip control when finishing

(*)There may be minor differences in the colour tone/lustre of Brilliant Coat grades due to the interference of light. Such differences have no effect on performance.

Application Range:

T1500Z

Superior turning quality thanks to Brilliant Coat, a new PVD coating with excellent lubricity.

A general purpose coated cermet grade capable of maintaining high-quality finished surfaces while providing excellent wear resistance.

T3000Z

A coated cermet grade designed with stability in mind that provides superior fracture resistance.

Covers a wide range of applications from roughing to finishing.

T1000A

An uncoated cermet grade designed with wear resistance in mind that provides long tool life and excellent wear resistance in continuous finishing and profiling applications.

T1500A

A general purpose uncoated cermet grade that provides excellent value for money and delivers improved finished-surface quality while providing good wear and fracture resistance.

Application Examples:

SCM415 Shaft

| Insert | TNMG160408N-SU(T1500Z) |

|---|---|

| Cutting Conditions |

vc=220m/min, f=0.26 to 0.34mm/rev ap=0.20 to 0.25mm Wet |

SCM420H Automotive Component

| Insert | TNMG160408N-LU(T1500Z) |

|---|---|

| Cutting Conditions |

vc=200m/min, f=0.15mm/rev, ap=1.00mm, Wet |

S48C Guide

| Insert | TPMT090204N-LU(1500Z) |

|---|---|

| Cutting Conditions |

vc=162m/min, f=0.13mm/rev, ap=0.55mm, Wet |

S45C Sleeve

| Insert | DCMT11T304N-LU(T1500Z) |

|---|---|

| Cutting Conditions |

vc=230m/min, f=0.10mm/rev, ap=0.50mm, Wet |

S43C Lower Shaft

| Insert | CPGT080208N-SD(T1500Z) |

|---|---|

| Cutting Conditions |

vc=140m/min, f=0.15mm/rev, ap=0.50mm, Wet |

S43C Machine Component

| Insert | VNMG160408N-FL(T1500Z) |

|---|---|

| Cutting Conditions |

vc=180m/min, f=0.20mm/rev, ap=0.20 to 0.90mm, Wet |

SAPH440 Press material Piston Parts

Standard life : Finished surface undulation

| Insert | DCMT11T308N-FB(T1500Z) |

|---|---|

| Cutting Conditions |

vc=360m/min, f=0.14mm/rev, ap=0.30mm(Rough) 0.02mm(Finish), Wet |

SCMr420H Clutch Parts

Standard life : Surface properties(White turbidity and exit burrs)

| Insert | DCMT11T304N-FB(T1500Z) |

|---|---|

| Cutting Conditions |

vc=220m/min, f=(1)0.15mm (2)0.12mm (3)0.18mm/rev, ap=0.25mm, Wet |

YouTube: