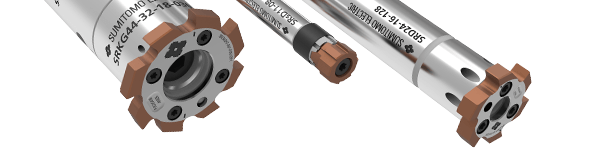

SR Reamer

SR Reamer

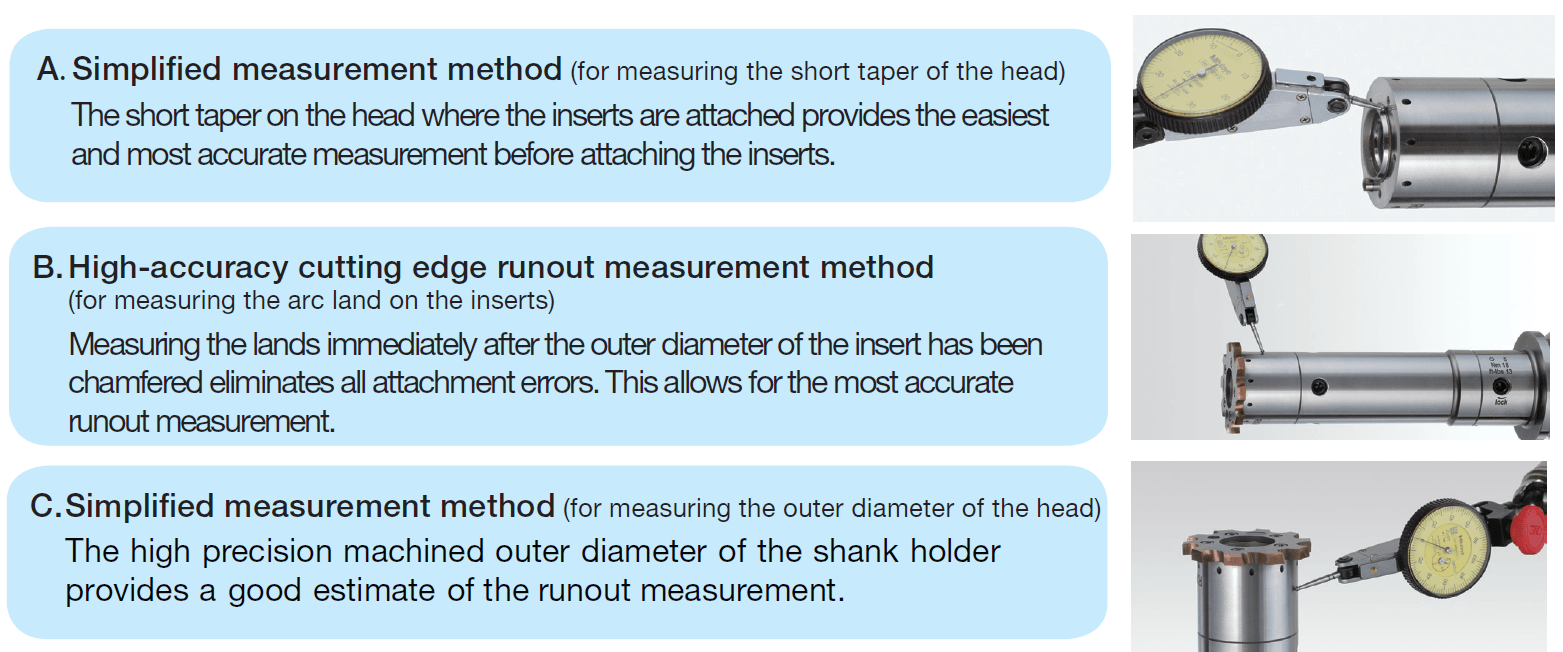

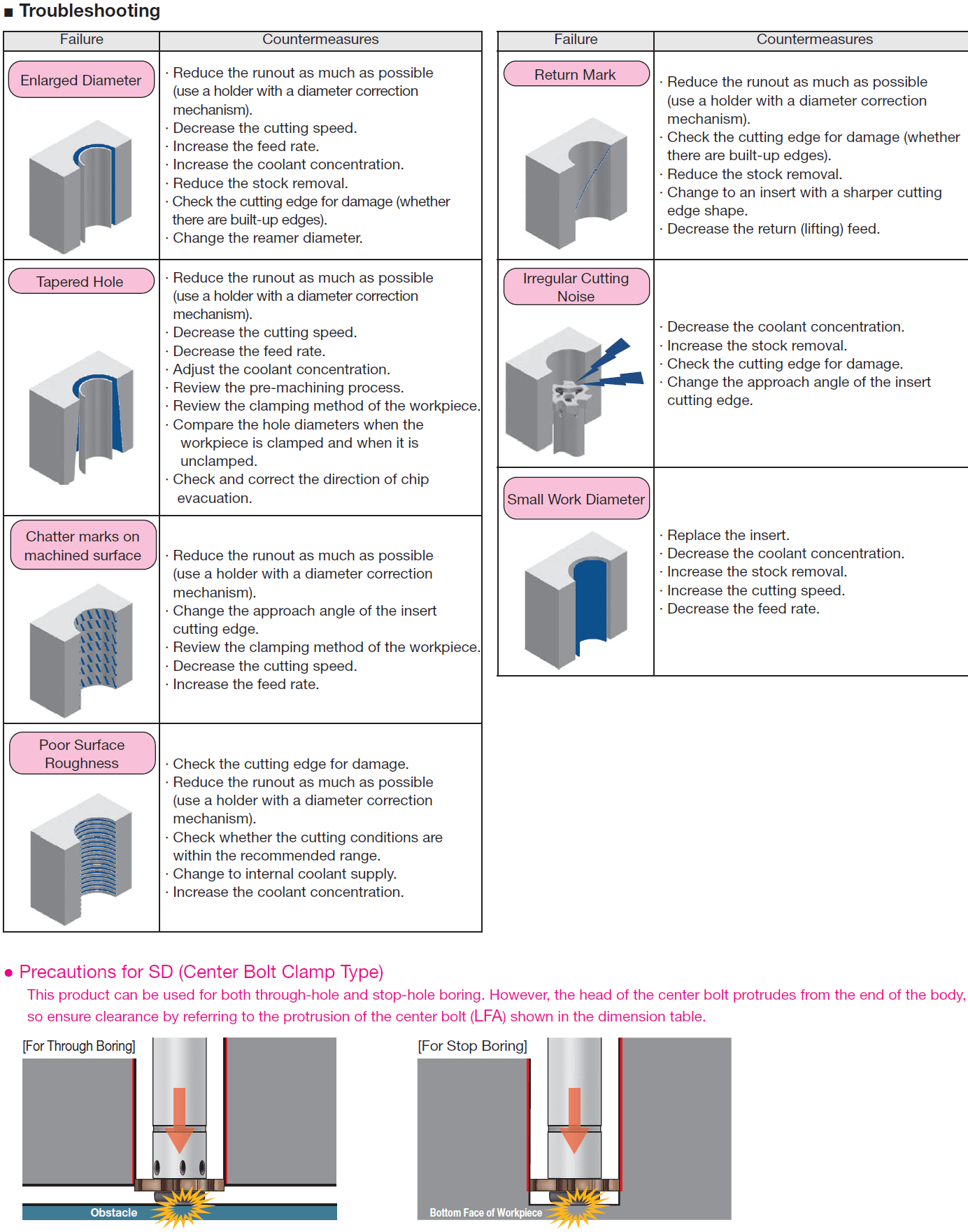

Features & Benefits:

Characteristics

● Achieves efficiency through high speed, high feeding ability vc= 164 to 1,640 SFM and F= .016 to .047 IPR (50~500m/min, f=.4~1.2mm/rev)

● Compatibility with a wide range of cutting conditions allows less strict cutting conditions and coolant control

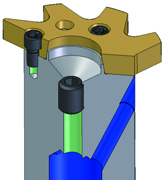

● Minimal cut edge length design eliminates biting and tearing for improved quality and reliability

● Adoption of indexable cutting edge design improves reliability of quality and tool life, eliminating variability in tool life among regrind inserts.

● Cutting edge diameters from ø7.6 to ø200.200 mm available. Now offering SR Large, featuring diameter sizes: ø139.801 – ø200.200 mm

● Easy insert replacement

● Flexible tool overhang lengths possible by combining the modular extension/ arbor and holder with correction mechanism

High Efficiency Reamers

Positioning based on HSK taper has two points of contact with radial runout accuracy < 4 µm and face contact guarantees excellent power transmission. SR Reamer achieves efficiency through high speed, high feeding ability (SFM: 160 to 650 and feed rate: .0157 to .03937 IPR). Compatibility with a wide range of cutting conditions allows less strict running parameters and coolant control. Minimal cut edge length design eliminates biting and tearing for improved quality and reliability. Cutting edge diameters available from ø11.9 to ø140.6 mm.

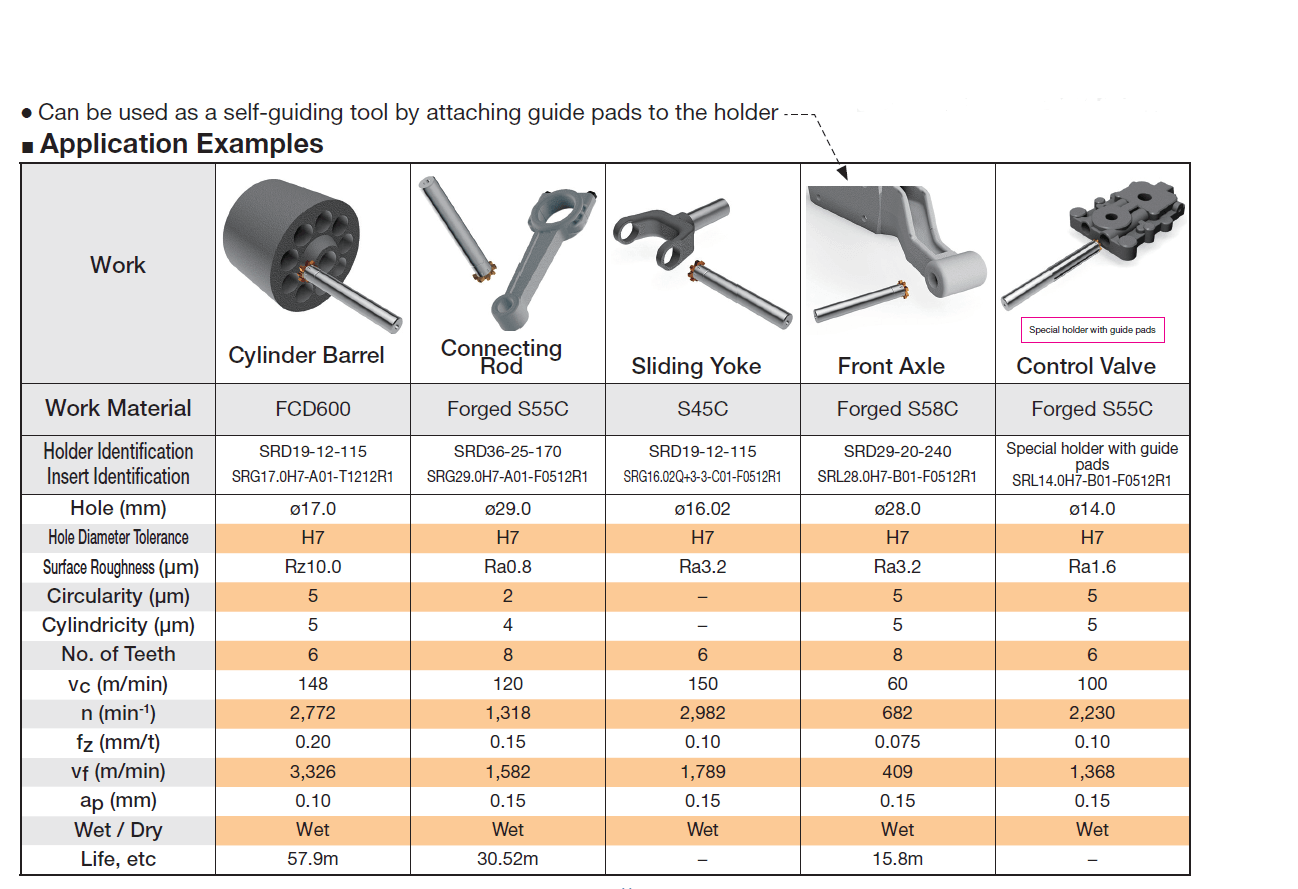

Application Examples:

Insert Lineup:

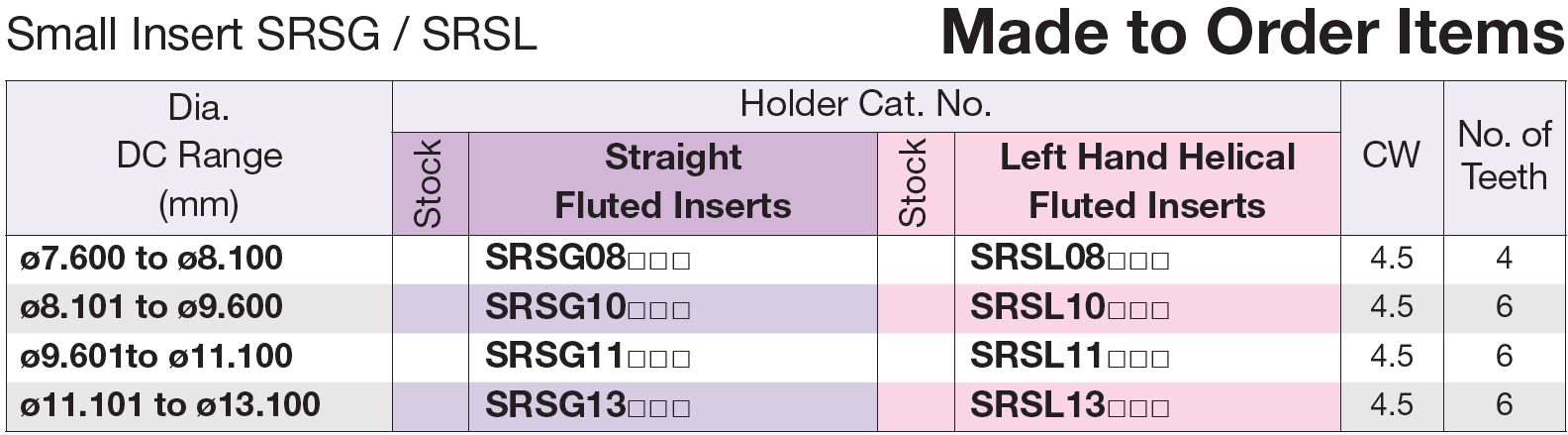

SRSG / SRSL – SR Inserts – Small

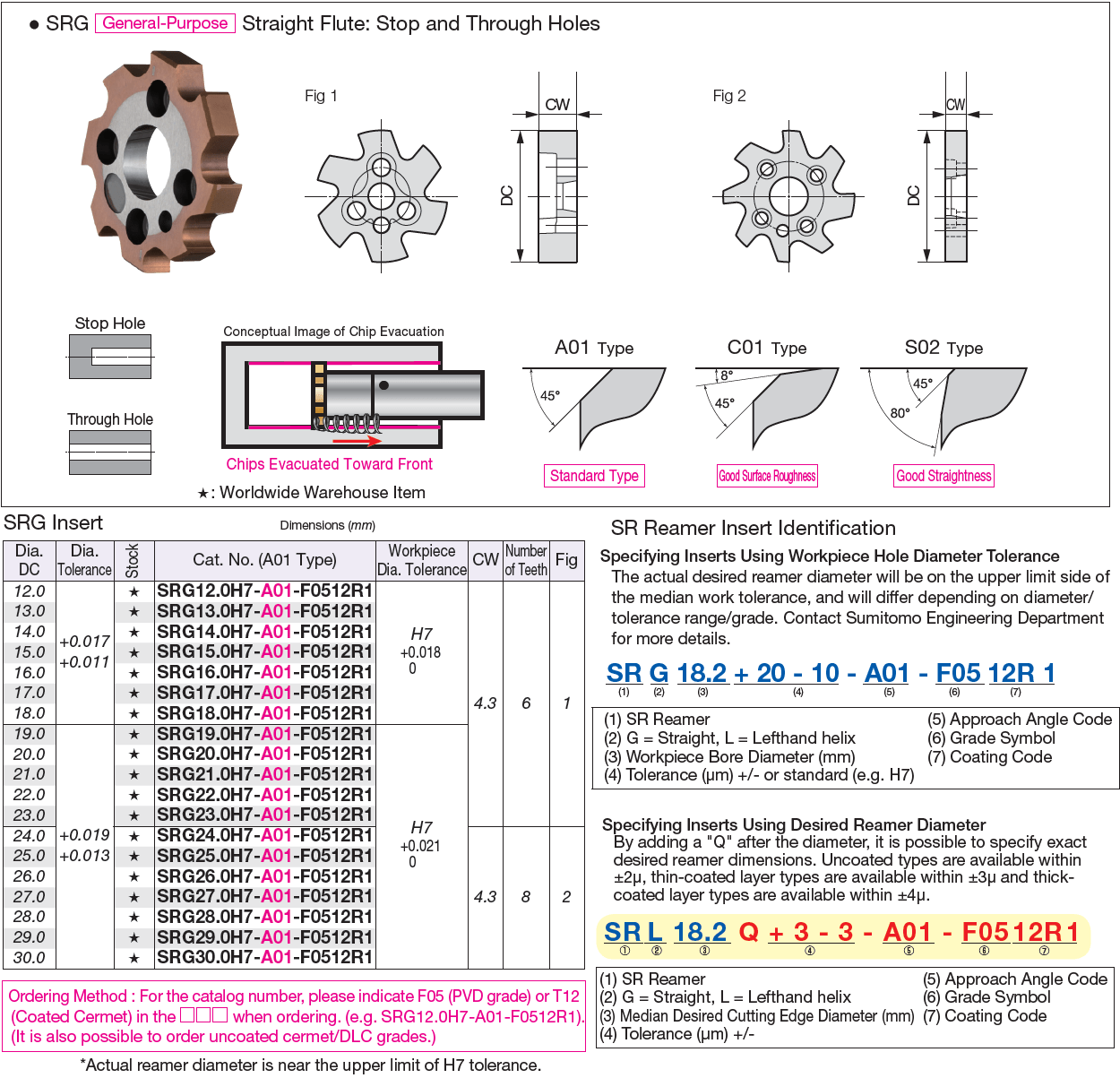

SRG – SR Reamer Inserts

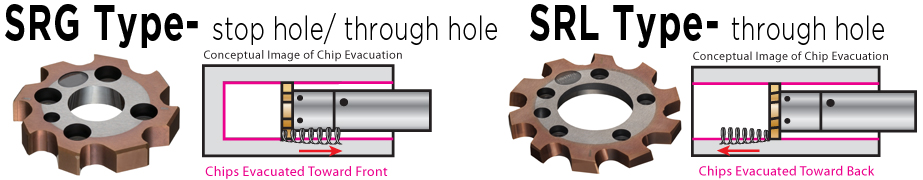

SRG Type for stop hole/ through hole boring, as seen above chips are evacuated toward the front.

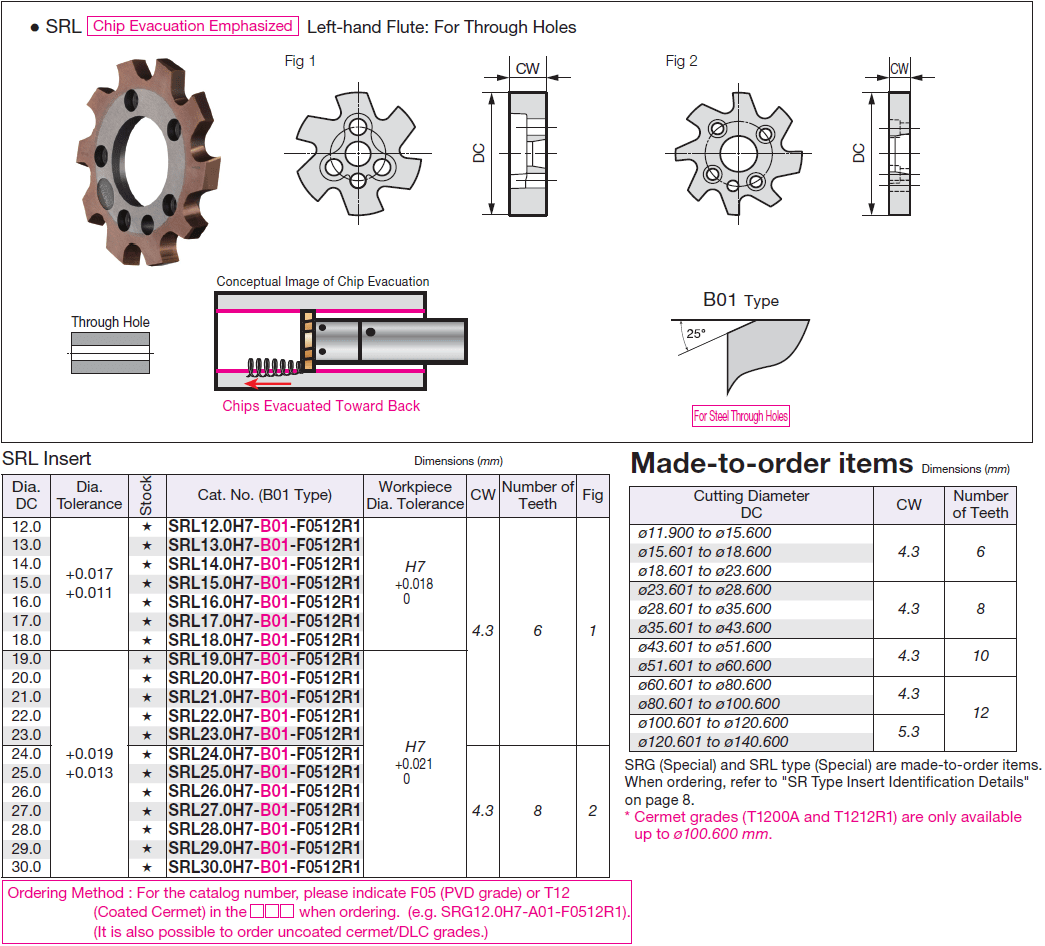

SRL Type for through hole boring, as seen above chips are evacuated toward the back.

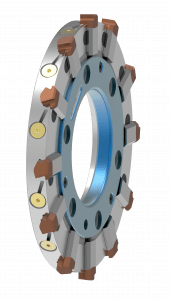

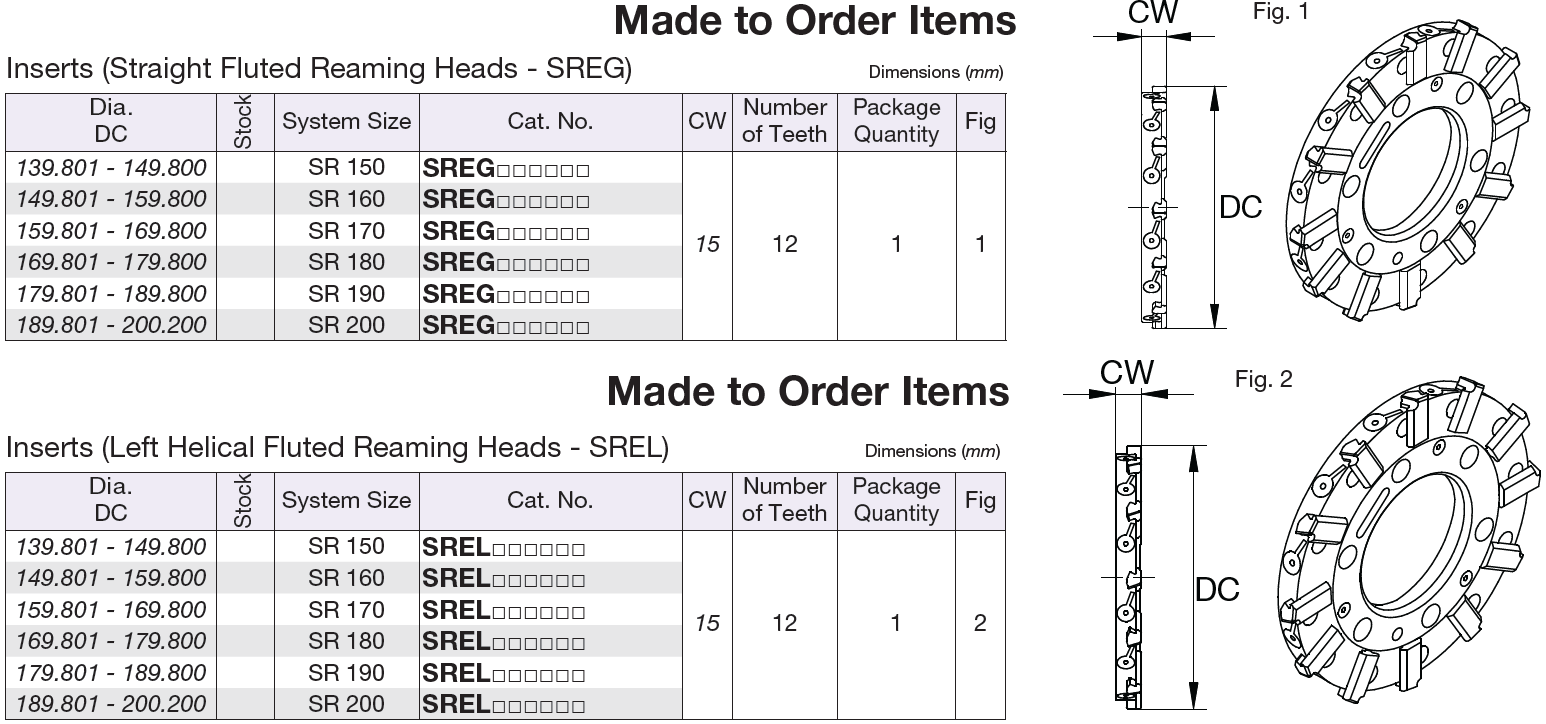

SREG / SREL – SR Reamer – Large

Videos: